| Density | 2.6 g/cc |

| Porosity | 0% |

| Thermal expansion | 4.2 x 10-6/°C |

| Resistance | |

| Room temperature | 6.00 Kg/mm2 |

| 1000 ° C | 6.05 Kg/mm2 |

| 1,250° C | 7.10 Kg/mm2 |

| 1350 ° C | 7.40 Kg / mm2 |

| Heat transmission | 7.8 Kcal/h/cm2 |

radiant tubes

RADIANT TUBES FOR HIGH TEMPERATURES

INNOVATIVE INEX PRODUCTS

Sitec Srl markets and sells radiant tubes

produced by Inex, a leader in the industry. These composite radiant tubes

(silicon carbide and silicon matrix) are produced using an innovative, simple but effective manufacturing process which implicates high performance at highly competitive costs.

The classic radiant tubes in nickel alloys or in monolithic ceramic may not last as long due to several factors:

- Thermal shock

- Vibrations

- Creep

- Melting

- Oxidation

- Carburation

In contrast, the Inex products, from direct flame radiant tubes

to finned tubes etc, are characterised by a very high degree of thermal shock resistance which allows:

- installation in furnaces with operating temperature above 950°

- reduction of heating times equal to 100%, reaching a temperature of 985 ° in 4 hours rather than the standard requested 12.

THE VARIOUS APPLICATIONS OF INEX RADIANT TUBES

The radiant tubes produced by Inex, successfully used since 1988 around the world, are ideal for thermal treatment in various industrial processes such as:

- Annealing

- Cementation

- Solubilisation

- Toughening

- Carbonitriding

- Ferritic carbonitriding

- and with the following atmospheres:

- Endothermic

- Gas enriched with carbon

- Gas enriched with ammonia

- Nitrogen

- Endothermic / Ammonia (50/50) mixtures

KEY PHYSICAL PROPERTIES

STANDARD SIZES

| 25.4 | mm | diam. | 3.2 | mm | thickness |

| 38.1 | mm | diam. | 3.2 | mm | thickness |

| 60.3 | mm | diam. | 3.2 | mm | thickness |

| 70.0 | mm | diam. | 3.2 | mm | thickness |

| 82.5 | mm | diam. | 3.2 | mm | thickness |

| 114.3 | mm | diam. | 3.2 | mm | thickness |

| 130 | mm | diam. | 3.2 | mm | thickness |

| 152 | mm | diam. | 3.2 | mm | thickness |

Larger sizes are under development and requests for special sizes may also be taken into consideration.

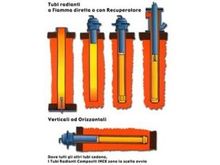

RADIANT TUBES

Direct flame radiant tubes or with vertical or horizontal recuperator

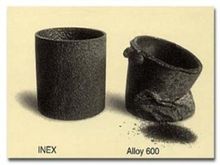

INEX TUBE IN SI / SIC COMPOSITE

The INEX tube in Si / SiC composite, on the left, has been tested for 360 hours. The one in Alloy 600, on the right, has been tested for less than an hour.

Test conducted by Hi-Tech Ceramics, Alfred, NY, USA.

U-SHAPED RADIANT TUBE

Direct flame radiant tubes or with vertical or horizontal recuperator. For available sizes see the table opposite.

AVAILABLE SIZES OF U-SHAPED RADIANT TUBES

| External diameter | 114 mm |

| Internal diameter | 105 mm |

| Wheel base | 229 mm |

| External diameter | 152 mm |

| Internal diameter | 142 mm |

| Wheel base | 229 mm |

| External diameter | 152 mm |

| Internal diameter | 142 mm |

| Wheel base | 305 mm |

FINNED TUBES

Special shaped tube with spiral fins designed and manufactured exclusively by Schunk-Inex with resistance up to temperatures of at least 1,350° C.

The company's finned tubes can withstand exceptionally high temperatures for a long period of time and increasing combustion efficiency, while simultaneously ensuring a signficant saving. Features:

- high operating temperatures, up to 1,350 ° C

- long-lasting tubes

- reduction of gas consumption

- improvemed heat recovery

- improved combustion efficiency

- proven savings

SITEC srl | 13, Via Romagnosi - 20021 Bollate (MI) - Italia | P.I. 01685020388 | Tel. +39 02 33300543 |

info@sitecsrl.com

|

Informazioni Legali

|

Privacy Policy e Cookie Policy