| AC 100 | AC 200 | AC 250 | Graphite | ||

| Fibre Correlation/ Volume | % | 40 | 40 | 50 | === |

| Process temperature | °C | 2000 | 2000 | 2000 | 2000 |

| Density | g /cm3 | 1.7 | 1.7 | 1.7 | 1.7 |

| Resistance to curving | Kgf / mm2 | 8 | 15 | 55 | 4 |

| Resistance to compression | Kgf / mm2 | 8 | 10 | 24 | 8 |

| Charphy impact level | Kgf / cm / cm2 | 10 | 13 | 53 | 2 |

| Thermal expansion refering to the length and thickness | 10-6 / ° C | 2 === | 1.1- 8.4 | 0.6 - 8.2 | 4 - 4 |

| Thermal conductivity refering to the length and thickness | Kcal / m hr ° C | 15 === | 30 - 11 | 59 - 9 | 100 - 100 |

| Specific heat 20° C 1,200° C | cal / g ° C | From 0.18 to 0.49 | From 0.18 to 0.47 | 0.18 - 0.45 | 0.17- 0.17 |

| Shore Hardness | - | 75 | 81 | 85 | 40 |

| Resistivity, volume | n‡ cm | 3200 | 2500 | 1700 | 1000 |

carbon fibre

CARBON FIBRE PRODUCTS

PRODUCTS AND ITEMS FOR THERMAL TREATMENT

Thanks to a consolidated and efficient network of international partnerships, Sitec Srl researches and locates the most effective solutions to provide a comprehensive range of state of the art products and top quality technological craftmanship. These include the sale of carbon fibre

products reinforced c/c conventional and unconventional composite, manufactured by Across Co. Ltd. From graphite felts

to welding tools, from the drum for thermal treatment

to the conveyor belt, the c/c conventional composite offers an endless range of advantages:

- Excellent resistance to temperatures higher than 1,2OO° C

- Low coefficient of thermal expansion

- High resistance to thermal shock

- Improved abrasion resistance

- High resistance combined with lightness

- High elasticity modulus

- High thermal conductivity

- High corrosion resistance

- Excellent electrical conductivity

- Rapid rise and fall in temperature

- Improved fracture resistance

Parallel to the advantageous characteristics, it is, however, well-known that the c/c composite also has various drawbacks such as the lack of regularity of the physical and mechanical properties, its high cost, low resistance to bending and so on.

In order to overcome these shortcomings, Across Co. Ltd has developed and patented an innovative production system of the c/c composite, based on the preparation of the pre-formed fibres with powder binder into a carbon matrix. The compound obtained this way is then placed in thermoplastic hoses which can then be woven like a carpet and introduced hot into an outlet. The result is a c/c composite which, unlike the classic production method, has an exceptional degree of uniformity and very high resistance.

PROPERTIES OF ACROSS' C/C COMPOSITE, COMPARED TO CONVENTIONAL GRAPHITE

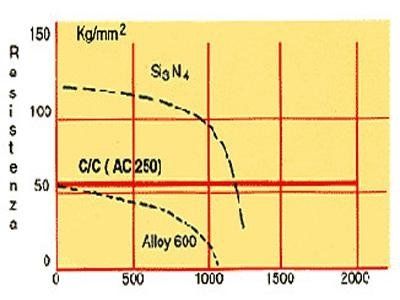

THE EFFECT OF THE HEAT ON THE RESISTANCE

Unlike ceramic and nickel alloy materials, that gradually lose their strength as the temperature increases, the AC 250 Across fibres preserve their resistance constant, even at temperatures higher than 2,000° C.

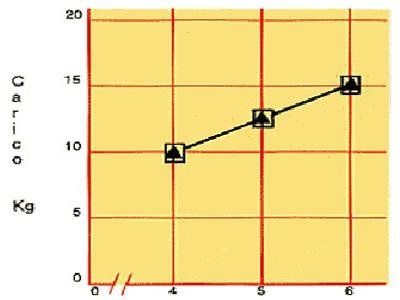

THE EFFECT OF HEAT ON THE BENDING RESISTANCE

The bending resistance, in relation to the load, also remains unchanged for long periods of time, without being influenced by temperature.

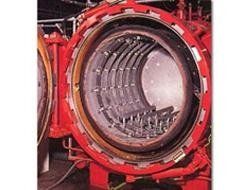

Coating of hot chambers for vacuum furnaces

AC 200 carbon fibre welding tools

Loaded springs for thermal treatment. The fibres follow the spiral

Tie rods and nuts

Drum for thermal treatment, rugged, lightweight and long lasting

Conveyor belt for use over 1,200° C

SITEC srl | 13, Via Romagnosi - 20021 Bollate (MI) - Italia | P.I. 01685020388 | Tel. +39 02 33300543 |

info@sitecsrl.com

|

Informazioni Legali

|

Privacy Policy e Cookie Policy